The Beam trolley is a must-have tool for every weaving mill, because the weaving shaft has a high weight, usually between 1000-2500kgs, it is difficult to move the shaft car manually, and for SUNTECH motorized beam trolley, it can not only be used to precisely load and unload the weaving beam on the loom, but most importantly, the beam trolley can transport the beans to the designated production area for the next step.

That’s why motorized beam trolley & beam transport trolley is most popular for the weaving factory now.

SUNTECH have over 50 years of innovation for motorized beam area, except to provide the standard machine model, we also support the customized solutions for our customers.

Let me introduce you to three of the most popular beam trolleys in our machine collection:

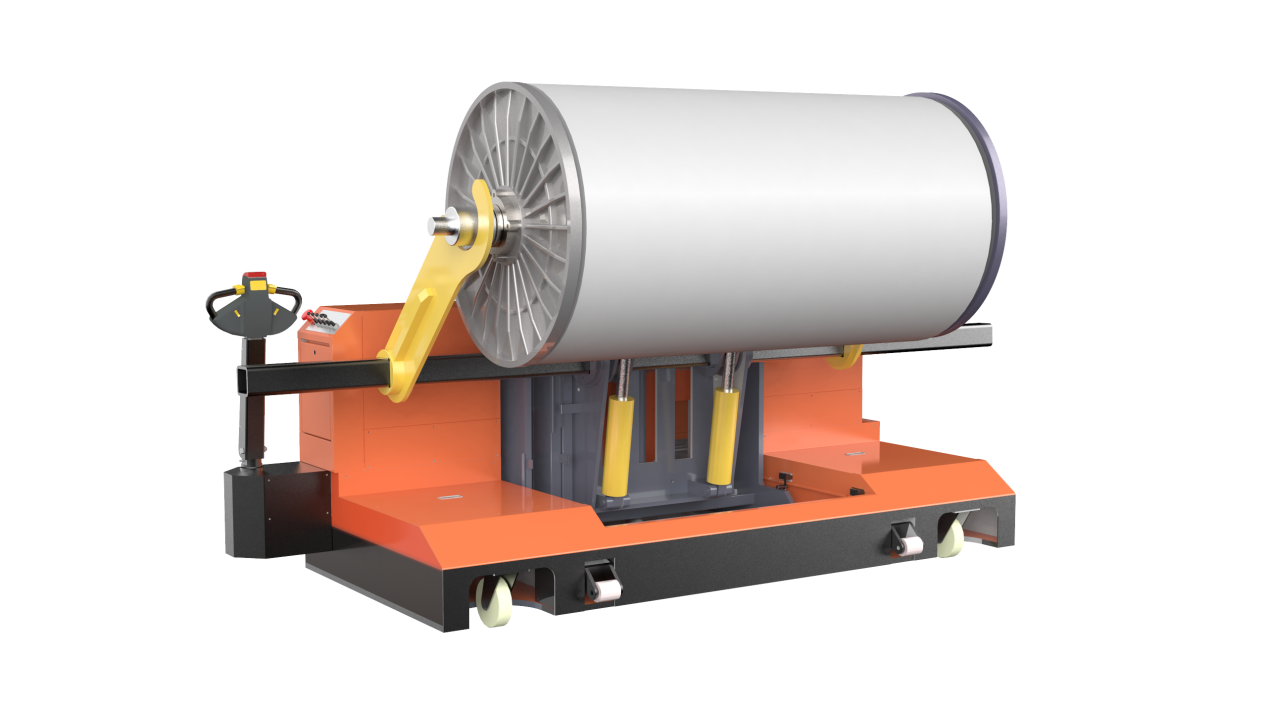

1, (Motorized beam trolley) Motorized Warp Beam High Lift Trolley

1, (Motorized beam trolley) Motorized Warp Beam High Lift Trolley

Motorized Warp Beam High Lift Trolley is suitable for Upper Beam transporting, inserting in weaving machines; the removal of batches from the winder; the loading of warp beam storage racks and batch storage racks; the mounting of sectional beams in knitting machines as well as the handling of non-woven material rolls. Polyurethane running wheels mounted one after the other in an oscillating manner lead to low ground contact pressure with high stability. Telescopic supporting rollers with safety control ensure a safe operation.

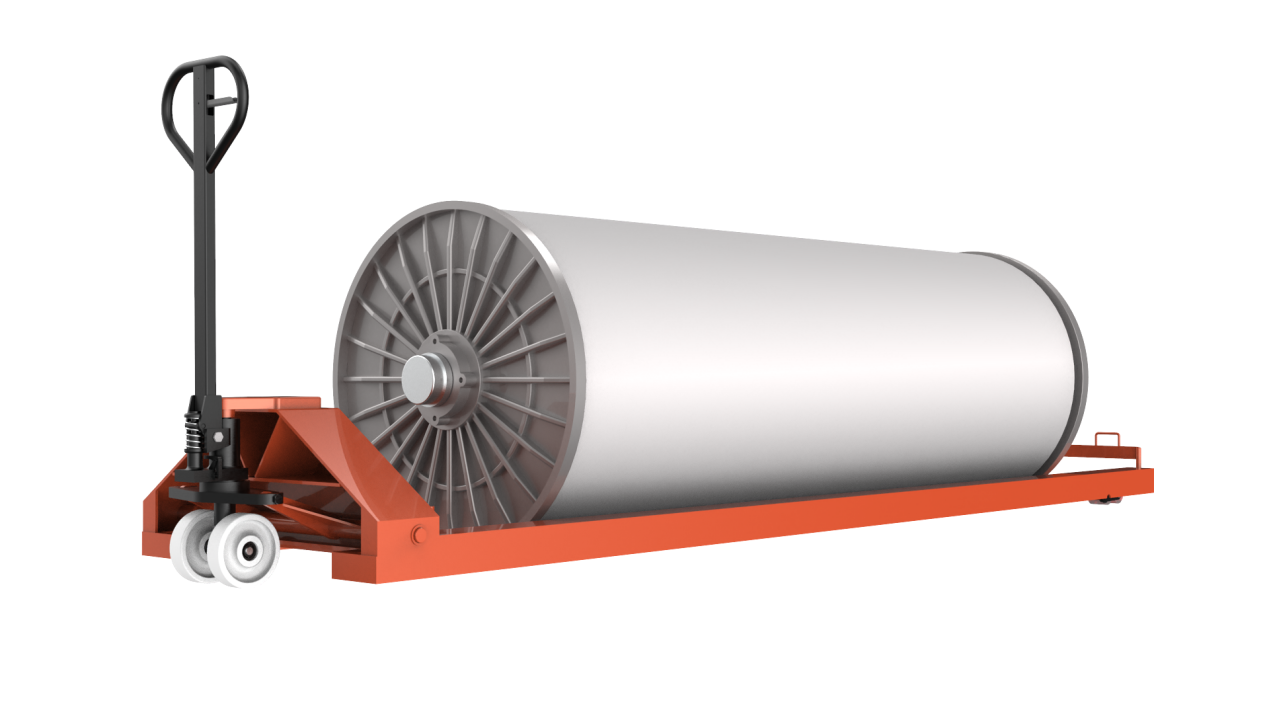

2, Beam transport trolley (Electric Warp Beam Low Lift Trolley)

This type trolley is designed for the easy transport of warper’s beams and warp beams weighing up to 2000kg and is also suitable for longer distances, e.g. from the warping frame to the warping machine or to the warehouse. Depending on the warp beam length and the warp beam diameter, this trolley is also able to cope with gradients while transporting load. The sensitive driving and braking motions make it an uncomplicated transporter. The central drive allows a good traction, and the spring-loaded support wheels ensure good and safe driving characteristics.

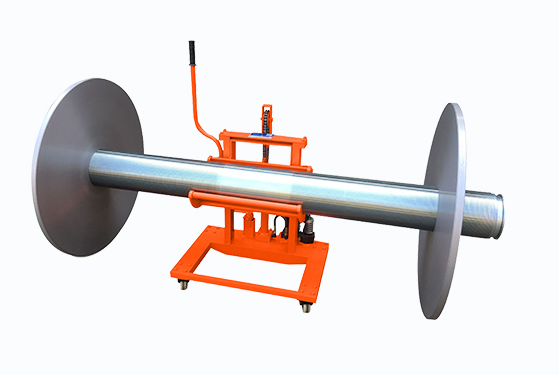

3, Empty warp beam transport trolley

The empty warp beam trolley is suitable for empty beam transporting, loading/unloading in loom shed and beaming section. Carrying capacity up to 250kgs and beam flange diameter up to 1000mm. Beam barrel dia. up to 300mm.

Here are some suggestions for choosing a most suitable beam transport trolley.

1, Battery type.

SUNTECH trolley adapt Gel battery, Free maintenance, No need balanced charging, working life is twice of lead acid battery, Gel battery is more stable under high load, and environmental protection , the electrolyte can be used as fertilizer , the battery grid can be recycled.

2, whether the warp beam transport trolley support micro setting on the loom width direction.

SUNTECH trolley have the micro setting on the loom width direction, The trolley is applicable for any weaving machines with their nominal working width 150-340cm without changing its size. A tranverse of 10cm for easy beam positioning.

3,Carrying capacity

Normally the beam trolley standard carrying capacity suppose within 1000-2500kgs (customized is accepted).

4, Warranty & after sales service.

Since the motorized trolley is very important for each weaving factory, so the customers is must very care about whether the trolley have a long warranty period & a fast after sales service.

SUNTECH support 12 months warranty period from date of shipping, and support 7*24hrs fast reply. We have a Independent department to help our customers solve the after sales service.

5, whether support customer to visit the machines before they confirm order ?

We have wide range customer cases in the world, so we are very happy to let our customers to see the machines before they confirm order.

If you want to learn more information about our beam trolleys or our customers , welcome contact with us by sales@suntech-machinery.com.