Understanding the diverse applications of automation technologies across various workflows is crucial for optimizing processes in the textile industry. Evaluating the cost-effectiveness of automation at different stages is essential to determine the feasibility of investing in transformative technologies. Enterprises can adopt a phased approach, starting with simpler processes and gradually expanding automation to ensure a seamless transformation.

For successful implementation, professional technical support and maintenance are imperative. Automation technology service providers offer essential consultation and support to guarantee a smooth execution of the automation transformation. Enterprises need to invest in trained professionals for the management and maintenance of automation systems, fostering sustainable development through training and recruitment efforts.

The integration of automation technology can lead to intelligent and data-driven management, significantly enhancing production efficiency and product quality. Implementing intelligent and data-driven management systems enables real-time monitoring and optimization of production processes. This, in turn, improves overall production efficiency and elevates product quality.

Revolutionizing the Textile Industry Through Artificial Intelligence

Intelligent Manufacturing: Advancements in Artificial Intelligence have ushered in a new era of intelligent manufacturing for the textile industry. Core technologies, such as feature extraction, optimization, planning, and scheduling, facilitate equipment scheduling algorithms, production process optimization, and quality inspection. The next stage involves enhancing intelligence through knowledge acquisition, knowledge base construction, deep learning, and optimization decision-making functions for true intelligent manufacturing.

Fabric Design and Analysis: Artificial intelligence has made significant contributions to fabric design, defect identification, fabric performance evaluation, cotton classification, and grading. Machine vision and machine learning technologies aid in the detection and analysis of defects, color differences, patterns, and other properties, solving long-standing technical difficulties and improving the level of identification and analysis in the industry.

Trend Research: Artificial intelligence technology has immense potential in trend research within the textile and fashion industry. Through computer vision and image processing technology, it can quickly analyze vast amounts of data to retrieve user preferences for color, patterns, and styles. By analyzing consumer clothing preferences, artificial intelligence can predict trends more accurately than traditional methods, becoming an ideal tool for textile and fashion innovation.

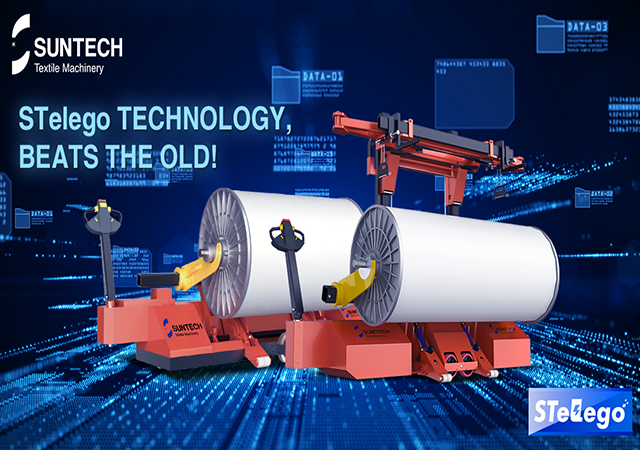

SUNTECH Automation: To address rising labor costs in the textile industry, SUNTECH Textile Machinery introduced the SUNTECH STelego (motorized beam trolley). This electrically powered trolley revolutionizes production by seamlessly unloading warp beams and cloth rolls from looms and transporting them to storage areas. The trolley improves handling efficiency by over 50%, saving more than 60% in labor costs. SUNTECH Textile Machinery remains committed to innovation, continually upgrading products to meet the evolving needs of the textile industry.

Seizing the Future with Artificial Intelligence in Textile

As the textile industry faces historic opportunities, embracing artificial intelligence technology is crucial for advancement. Leading as a strategic technology, AI can elevate intelligence levels across various textile fields, bringing about profound changes. The industry must accurately comprehend the distinctive features of AI technology and align them closely with the demands of textile enterprises to unlock its far-reaching implications. SUNTECH Textile Machinery, with its 50 years of expertise, stands at the forefront, contributing to the industry's transformation through intelligent machinery.