Introduction to Automatic Packaging Machines for Fabric Rolls

Automatic Packaging Machines play a pivotal role in efficiently packaging fabric rolls for various industries, ensuring ease of transportation and storage. These machines are tailored to handle fabric rolls effectively, offering both manual and automatic operation capabilities. Typically constructed from durable materials like stainless steel, these machines come in cylindrical shapes with loading capacities ranging from 200 to 400kg, accommodating a wide range of fabric types and sizes.

The Functionality of Automatic Fabric Roll Packing Machines

Automatic Fabric Roll Packing Machines are designed to streamline the packaging process for fabric rolls, including cotton, linen, and synthetic materials. These machines operate by securely rolling the fabric onto a spindle and utilizing belts and pulleys to maintain its position. Once secured, the machine automatically initiates the packing process, shaping the fabric roll into the desired form, such as roll to roll, plait to roll, or frame to roll, until fully packed.

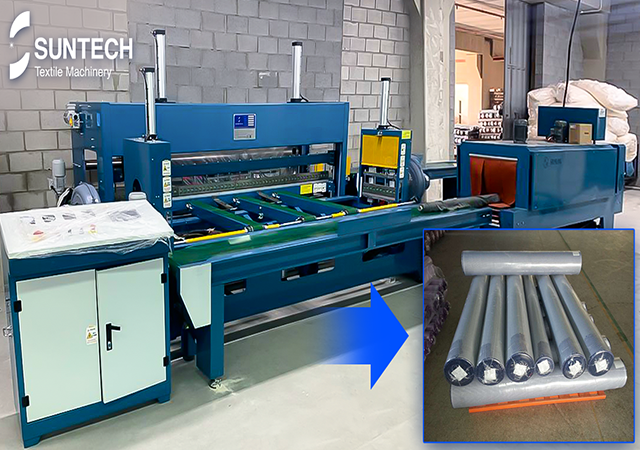

SUNTECH Automatic Fabric Roll Packing Machine (ST-ARPM)

The SUNTECH Automatic Fabric Roll Packing Machine represents a significant advancement in automated packing technology. Specifically engineered for vacuum-sealed and automated packing of fabric rolls, this machine offers a multitude of features aimed at reducing labor requirements and enhancing efficiency. With a capacity to handle 3360 rolls per shift, vacuum packing capabilities, labeling functionality, intelligent sorting, and seamless integration with ERP systems, the SUNTECH Automatic Fabric Roll Packing Machine revolutionizes fabric roll packaging processes, significantly increasing productivity and efficiency.

Features of ST-ARPM for Fabric Roll Packaging

ST-ARPM boasts a range of features designed to optimize efficiency and productivity in the textile industry. With a maximum capacity of 7 rolls per minute, this advanced system optimizes the packing process, resulting in increased output.

One notable feature of ST-ARPM is its intelligent classification capability, eliminating the need for manual sorting. Connected to ST-Thinkor, it allows for accurate fabric roll inspection and quality control, ensuring precise packing and labeling without human intervention.

The packing line offers customizable options to accommodate various fabric roll sizes, shapes, and types. Equipped with AI-powered technologies, it includes AI inspection to identify defects, sampling and taping functions for quality control, mapping and labeling functionalities for inventory management, and various packing methods for secure transportation.

Additionally, ST-ARPM encompasses a sorting function to organize rolls based on specific criteria, simplifying the distribution process.

Conclusion

The SUNTECH Automatic Fabric Roll Packing Machine streamlines fabric roll packaging processes, offering a fully customizable one-stop solution for manufacturers. By harnessing advanced technology and automation, it maximizes efficiency, accuracy, and quality control in fabric roll packaging, significantly reducing labor requirements and increasing productivity.