The jacquard loom machine is an important invention that has revolutionized the textile industry, which has allowed for intricate patterns and designs to be woven quickly and efficiently, completely transforming how textiles are made. The history of the jacquard loom machine has had a great impact on the industry, and continues to revolutionize modern-day textile practices!

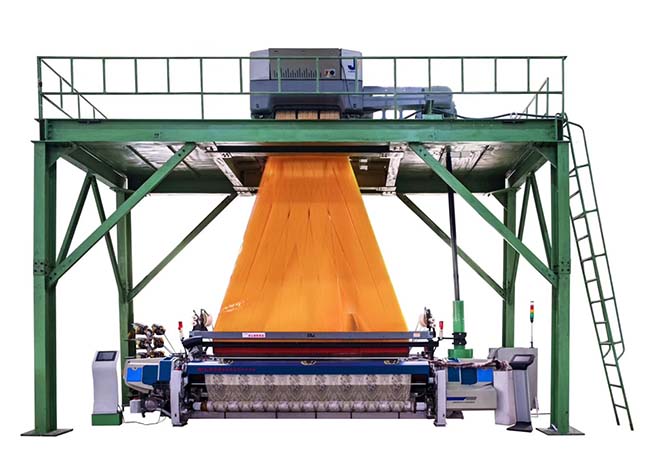

SUNTECH Jacquard Loom Machine

ST-JL is a type of jacquard loom machine that is manufactured by SUNTECH, which is suitable for weaving various jacquard fabrics, providing the most advanced jacquard solutions for the textile industry.

Main Parameters of ST-JL

Loom Width: 150, 190, 230(220),250,280,320,340,360;

Max. Speed: 250-400rpm;

Weft Insertion: 4 spacial connecting rod drive, no guiding hook, suspending single hook, or suspending double hook weft feeding;

Color Selecting: 8 electronic color selecting;

Shedding Device: Electronic jacquard, with 1344 needles, 2688 needles, 5000 needles, 10000 needles, and 16580 needles;

Let off: Electronic Let off, warp beam ∅800mm or ∅1000mm;

Take up: Electronic Take up, weft density range in 1-150 picks/cm, cloth roll diameter 600mm or cloth roll out of machine 1200mm;

Lubrication: Spray lubrication, Oil bath lubrication, Manual oil pump lubrication, and Oil gas lubrication, four methods exist together;

Automatic Weft Seeking: The electromagnetic clutch automatic weft seeking and heald reversing;

Automatic Controlling: PLC controlling system, auto-stop, auto-start, auto weft seeking, overcompensation, weft compensation, auto fault recognition;

Main Motor: 5.5-7.5KW

Jacquard Weaving Organization

The jacquard weave is to place the yarn cushion on some needles selected according to the pattern requirements to knit into a circle. The knitting needles that are not filled with new yarn do not form a circle, and the yarn is a floating line. These knitting needles do not participate in weaving Later, the weave formed by such weaving is called jacquard weave, and its structural units are coils and floats. Jacquard can be divided into single-sided and double-sided, single-color and multi-color.

1. Uniform Jacquard Weave on Single Side

Generally, the weaving fabric will use different colors or different types of yarns, and the number of coils on each wale is the same, with the size the same. The pattern effect is mainly formed by the combination of different yarns.

2. Uneven Jacquard Weave on Single Side

This type uses more monochrome yarns. Some knitting needles do not knit for several consecutive courses, so that form elongated loops, that is, the loops are not the same size.

3. Double-sided Complete Jacquard Weave

In each knitting system, all dial needles participate in the weaving of the back stitches. It is also called double-sided jacquard on the reverse side of the horizontal stripe.

4. Double-sided Incomplete Jacquard

The reverse side of vertical stripes and sesame dots is a double-sided jacquard weave in which each row is alternately woven with 2 colored yarns, so it is also called an incomplete jacquard weave.

5. Threadbare Jacquard

It refers to the weave in which the front stitches are transferred during the knitting process so that the reverse stitches of the ground weave are exposed on the front pattern of the jacquard. The pattern part on the front is composed of reverse coils, showing a single-sided structure, and the rest is a double-sided structure; the reverse side of the fabric is the same as the sesame dot jacquard, and the coils of the two colors are arranged alternately, showing the appearance of sesame dots. Because the pattern part in the open-bottom jacquard is woven on one side, the front of the fabric has a strong three-dimensional effect and the concave-convex effect is obvious.

Impact on the Textile Industry

The jacquard loom machine was invented in 1804 by Joseph Marie Jacquard that was designed to automatically weave complex patterns, making it an essential tool for the textile industry. The invention of the jacquard loom machine led to a dramatic increase in the variety and complexity of textiles that could be produced, also revolutionized the textile industry, making it much easier and faster to produce fabrics.

The jacquard loom machine was originally called the "Jacquard attachment" or "Jacquard head", for allowing more complicated designs to be made than with earlier looms. The jacquard loom machine had a major impact on the textile industry that increased the complexity and beauty of the fabrics that could be produced, and also made it possible to mass-produce fabrics with complex patterns. This allowed for a wider range of people to be able to afford these fabrics, as they were no longer only available to the wealthy.

Uses and Value of the Jacquard Loom Machine

Today, jacquard loom machines are still used to produce a variety of fabrics, including damask, brocade, tapestry, upholstery fabrics, and towel fabrics. Jacquard loom machines are valued for their ability to produce high-quality fabrics with intricate designs. The loom is also relatively easy to operate, which makes it a popular choice for textile manufacturers.

Conclusion

The invention of the jacquard loom machine has been beneficial for the textile industry. Not only has it increased productivity, but also allowed for more intricate and complex designs to be woven into fabric. This technology has advanced over time and can now produce high-quality textiles with greater speed, which makes it an ideal choice in a variety of industries. It remains one of the most important parts of textile production today and will continue to be so in years to come.