The evolution of fiber materials, particularly the advancement of functional fibers, plays a pivotal role in global competition, shaping the stability and security of industrial and supply chains while fostering industrial value and future opportunities. It's a cornerstone in modernizing the textile industry.

We're amidst a new industrial revolution, and the innovation in fibers must align with this wave, capturing its momentum. The industry's growth hinges on expanding horizons through integration, fostering intelligent paradigms through innovation, and crafting value by embracing sustainability. Key to advancing functional fibers are three primary focal points. Firstly, it's crucial to balance safety and progress, ensuring stability in industrial and supply chains, and pushing breakthroughs in key raw materials, technologies, and equipment for new fiber materials. Secondly, a forward-thinking approach is vital, encouraging interdisciplinary research and original innovation to cater to both present needs and future demands. Lastly, emphasis on enhancing quality and efficiency is essential—this involves upgrading both supply and demand sides, fostering collaborative innovation among industry, academia, research, and application sectors.

China has made significant strides in fiber materials, witnessing substantial progress in industrial scale, product quality, variety, functionality, and the shift toward greener, digitized fiber production. Director Cao Xuejun highlighted the immense impact of advanced functional fibers on enhancing textile supply quality, expanding textile application markets through high-performance fibers, and empowering green textile development through bio-based renewable and degradable fibers. To lead rather than follow, the industry must heighten its innovation drive, fortify its position in the textile industry chain, explore new scientific and technological frontiers for textile development, and intensify research on standards, certification, and rules to bolster the supply of low-carbon and green products.

In the realm of chemical fibers, they're broadly categorized as synthetic and semi-synthetic fibers, achieved through chemical methods. Synthetic fibers are further classified into modified and unmodified fibers. Modified fibers, such as Lycra and spandex, offer superior elasticity, comfort, and breathability and find extensive use in specialized clothing. Unmodified fibers like polyester, nylon, and acrylic boast durability, abrasion, and corrosion resistance, commonly employed in clothing and household items. Semi-synthetic fibers, like viscose, are created by blending natural and chemical fibers.

The raw materials for fiber production encompass fossil fuels such as coal, petroleum, natural gas, and natural materials like wood and plant fibers. Petroleum stands out as a primary raw material for synthetic fibers, while other fossil fuels and natural elements are also widely utilized. Textile companies select raw materials based on product quality, market positioning, and cost considerations.

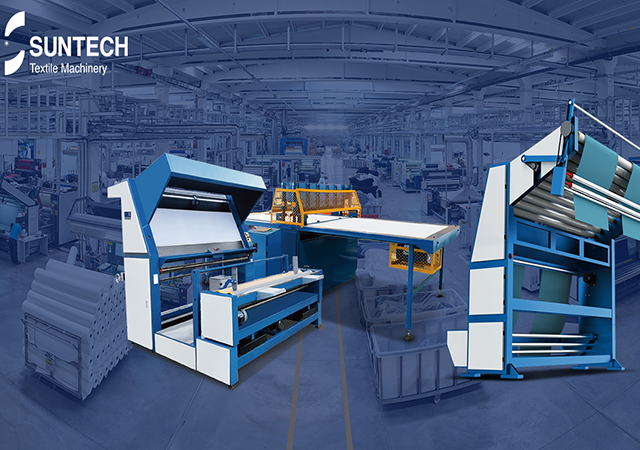

SUNTECH Textile Machinery offers an extensive array of products covering various fabric types, from pinking and weaving machines to fabric inspection machine. With an innovative approach and substantial experience, SUNTECH continues to lead the textile industry, welcoming collaboration opportunities and inquiries for their machinery.