In recent years, the added value of China's textile industry has increased year by year, with the total textile fiber processing, chemical fiber output, and textile and apparel exports ranking first in the world. "Structural adjustment", "technological innovation" and "green development" are still the main themes of the development of the global textile industry.

The development of the textile industry continues to improve

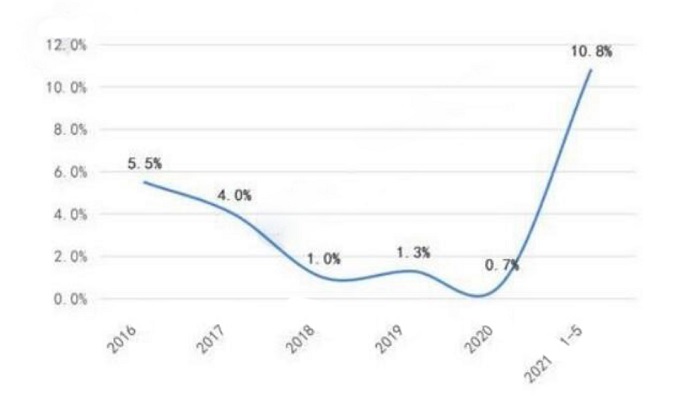

From the perspective of the added value of the textile industry, the added value of the textile industry will continue to be in the growth range from 2016 to 2020, but the growth rate has declined year by year. By the first five months of 2021, the cumulative added value of the textile industry will show a recovery and substantial growth of 10.8%.

2016-2021 year-on-year growth in the added value of the textile industry

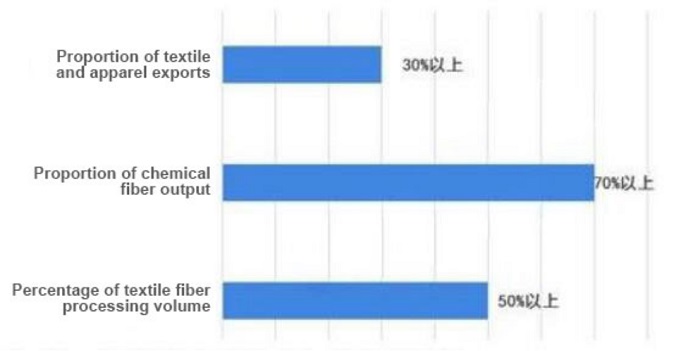

From the perspective of China's textile industry's global market position, in 2020, China's total textile fiber processing will reach 58 million tons, accounting for more than 50% of the world's total fiber processing; chemical fiber output will account for more than 70% of the world's textiles; Clothing exports amounted to 299 billion US dollars, accounting for more than one-third of the world's proportion, ranking first in the world.

2020 proportion of China's textile fiber processing, fiber production and textile exports in the global market

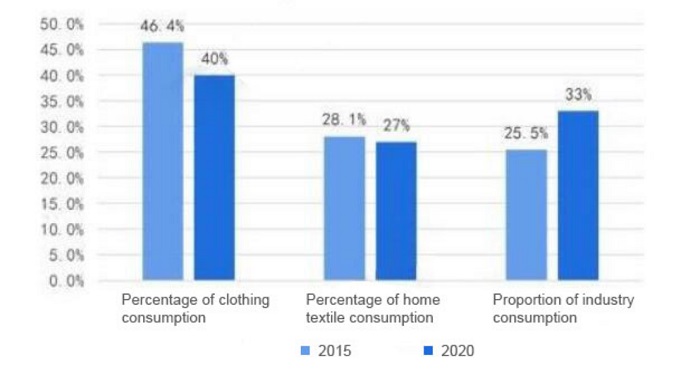

The proportion of fiber consumption in the three terminal products of clothing, home textiles and industrial use will be adjusted from 46.4:28.1:25.5 in 2015 to 40:27:33 in 2020. The proportion of industrial consumption has increased by 7.5 percentage points, and the terminal consumption of clothing and home textiles The proportions have all declined. By the end of 2020, China's industrial fiber processing volume reached 19.1 million tons, an increase of more than 40% over 2015, effectively meeting the needs of diversified, multi-level, and multi-field markets. As a whole, it reflects the gradual optimization of the industrial structure of the textile industry.

2015-2020 Changes in the proportion of fiber consumption in the three major terminal products of the textile industry

The ecological environment for technological innovation in the entire industrial chain of the textile industry has continued to improve, and great progress has been made in the construction of industrial innovation platforms, enterprise R&D investment, and equipment manufacturing. There are a number of "stuck neck" technical problems in the fields of fiber materials, green manufacturing, and textile machinery. Was successively broken through.

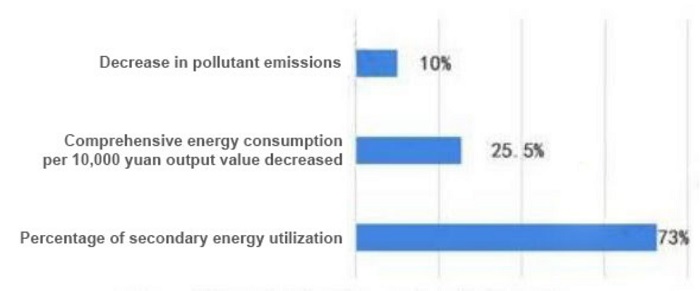

The energy structure of the textile industry continues to be optimized, the proportion of secondary energy reaches 72.5%, the energy utilization efficiency is continuously improved, the comprehensive energy consumption per 10,000 yuan of output value has dropped by 25.5%, and the industrial waste water discharge and the discharge of major pollutants have dropped by more than 10%. . This reflects the remarkable results of green development in the textile industry.

It can be seen that the overall textile industry is developing rapidly and the prospects are considerable. The current industry bottleneck lies in technological innovation, equipment manufacturing, and green environmental protection. In recent years, the textile industry has gradually shown green development. This is also the future direction. The world has already placed research centers. In the fields of fiber materials, green manufacturing, textile machinery and other fields, green intelligent manufacturing has become a breakthrough in the industry.

Suntech has been deeply involved in the intelligent machinery industry for 50 years and is committed to the design and development of intelligent textile machinery. It has international leading technology. It has opened up production lines for intelligent textile machinery, intelligent storage and transportation, hygiene and intelligent looms, and provided professional solutions. It has successfully developed fabric inspection machines. , Cloth inspection packaging line, beam stacker, meltblown machine, mask machine, rapier loom and other star products. Among them, intelligent cloth inspection machine, beam stacker, rapier loom, took the lead in opening up new ideas for textile machinery and subverting industry cognition , Has won many patented technologies, through automation, intelligence, data design and application, to achieve efficient production, reduce resource waste, save labor, reduce production costs, and help the green transformation of the textile industry.

Among them, the rapier loom integrates the functions of traditional looms and intelligent cloth inspection machines, and uses intelligent applications to accurately design and integrate the various weaving processes. The finished cloth can directly enter the automatic cloth inspection link to achieve the optimal production state. Ensure the quality of cloth rolls and save a lot of manpower and material resources.

Customers who have used Suntech rapier looms are full of praise for this loom, which can be called artificial intelligence in the loom industry. According to statistics, this loom can save 50% of labor costs and 50% on average, and increase production by 50%. Efficiency, in addition to automatic fabric inspection, it can also be controlled by PLC, automatic weft seeking, servo electronic warp let-off, servo electronic take-up, so that every step of the textile is intelligent, and the production speed is greatly improved. Welcome to inquire.