The international epidemic situation has become increasingly severe. Since the discovery of the mutant virus in the United Kingdom, countries have successively discovered the mutant virus. This is undoubtedly a heavy blow to the vaccine results.

At present, the mutant new coronavirus discovered in the UK has appeared in 50 countries and regions around the world, and the mutant new coronavirus discovered in South Africa has appeared in 20 countries and regions. Japan also reported to the WHO last week that a new variant of the new coronavirus has been found in travelers from Brazil, and Brazilian researchers have discovered another similar variant of the new coronavirus.

Michael Ryan, the head of the WHO's health emergency project, said that nearly 5 million new cases of new coronary pneumonia have been added globally in the past week. Considering the dynamics of the spread of the virus, the future epidemic situation may be more severe. In the northern hemisphere, especially in Europe and North America, people are entering indoors due to the cold and social gatherings have increased, and a series of factors have increased the spread of the virus in many countries.(Click to share to LinkedIn)

The Japanese government has determined that it will completely prohibit foreigners from entering the country, and countries have successively adopted a “closed door” policy, hoping to control the spread of the virus by prohibiting circulation.

At present, China, where the epidemic situation is relatively good, is also discovering imported cases one after another, and inspections in various places have become strict. You must wear a mask and show a health code when entering and leaving public places. Before the effectiveness of the vaccine has been proven, wearing a mask is the best defense.(Click to share to Facebook)

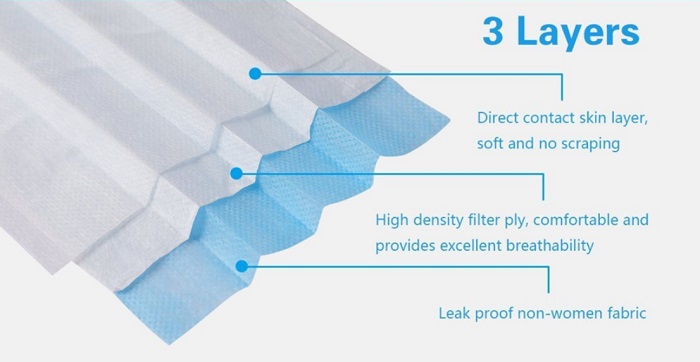

When it comes to masks, one has to mention non-woven fabrics. The three-layer fabric of the mask includes the outermost layer of spunbonded non-woven fabric, which is used to block external debris and large particles of bacteria, and the middle layer of spun-melted non-woven fabric. It mainly adsorbs bacteria through static electricity, and the innermost layer of spunbonded non-woven fabric is used to isolate the liquid sprayed by the patient.

It can be said that the three-layer fabrics of masks are all non-woven fabrics, which shows that non-woven fabrics are widely used. Data show that from 2015 to 2019, the total industrial output value of my country's non-woven fabric industry has shown a slow growth trend. In 2019, the total industrial output value of the non-woven fabric industry increased by 1.85% year-on-year.

.jpg)

Analysis of the total industrial output value of China's non-woven fabric industry from 2015 to 2019

What is non-woven fabric?

Non-woven fabrics, also known as non-woven fabrics, are composed of oriented or random fibers. It is called cloth because of its appearance and certain properties. It is not interwoven and knitted together one by one yarns, but the fibers are directly bonded together by physical or chemical methods. This is the biggest difference between it and ordinary cloth. Therefore, non-woven fabrics cannot draw out the thread.

Features of non-woven fabric

1. Non-woven fabric breaks through the traditional textile principle, without warp and weft, it is very convenient to cut and sew, light in weight and easy to shape.

2. Short process flow, fast production rate, high output, low cost, wide use and multiple sources of raw materials.

3. Compared with textile fabrics, it has poor strength and durability and cannot be cleaned like other fabrics.

4. Since the fibers are arranged in a certain direction, it is easy to split from the right angle direction, etc. At present, when non-woven fabrics are produced, how to prevent cracking is considered.

Non-woven fabrics are widely used

Non-woven fabrics are roughly divided into the following categories:

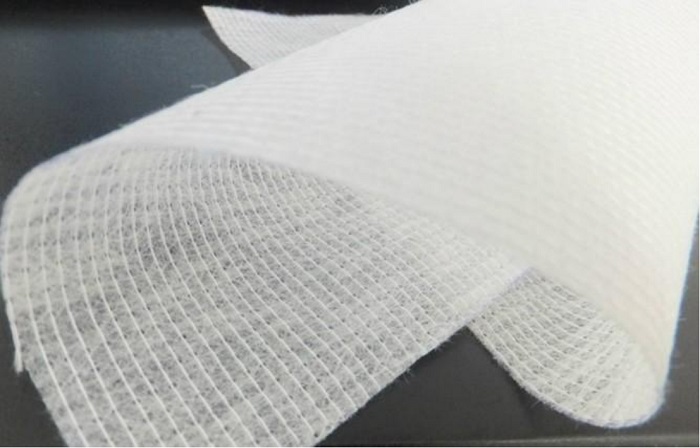

(1) Spunlace non-woven fabric

The high-pressure fine water jet is sprayed onto one or more layers of the fiber web to make the fibers entangled with each other, so that the fiber web can be reinforced and possess a certain strength.

Features:

1. Flexible entanglement, does not affect the original characteristics of the fiber, and does not damage the fiber.

2. The appearance is closer to traditional textiles.

3. High strength and low fluffing.

4. High moisture absorption, fast moisture absorption.

5. Soft hand feel and good drape.

6. Variety of appearance patterns.

7. Long production process and large area.

8. Complex equipment, high energy consumption and high water quality requirements.

Applications:

Medical curtains, surgical gowns, surgical drapes, medical dressing materials, wound dressings, medical gauze, aviation wipes, clothing lining base cloths, coated base cloths, advanced wipes for the electronics industry, cosmetic cottons, wet wipes, mask covering materials, etc.

(Suntech ST- SLNM Spunlace nonwoven machine)

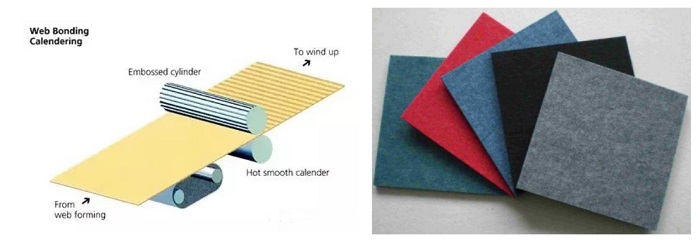

(2) Heat-sealing non-woven fabric

It refers to adding fibrous or powdery hot-melt adhesive reinforcement materials to the fiber web, and then the fiber web is heated, melted and cooled to form a cloth.

Features:

Surface bonding hot-rolled surfaces are mostly smooth, while point bonding hot-rolling is relatively fluffy.

Applications:

Production of covering materials for baby diapers and sanitary napkins, ointment base cloths, clothing linings, masks, etc.

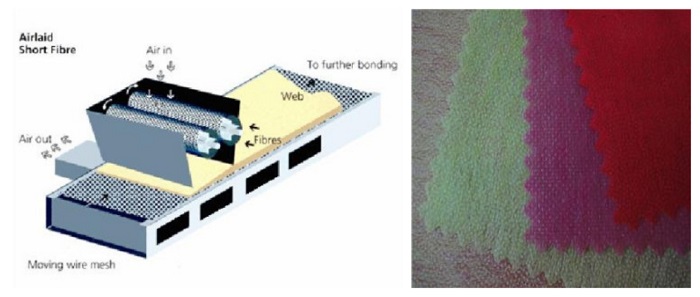

(3) Pulp air laid non-woven fabric

It can also be called dust-free paper and dry paper-making non-woven fabric. It uses air-laid technology to open the wood pulp fiberboard into a single fiber state, and then uses the air-flow method to agglomerate the fibers on the web curtain, and then strengthen the fiber web into a cloth.

Features:

good bulkiness, soft hand feeling, super moisture absorption performance.

Applications:

Medical sanitary materials, especially high-absorbency disposable sanitary products (such as diapers, sanitary napkins, wet face towels, wipes, etc.).

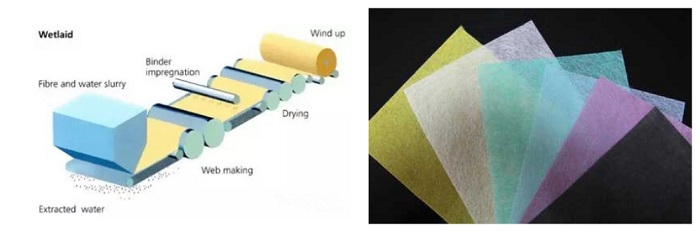

(4) Wet-laid non-woven fabric

The fiber raw materials placed in the water medium are opened into single fibers, and different fiber raw materials are mixed at the same time to form a fiber suspension slurry, which is transported to a net forming mechanism, and the fibers are formed into a net in a wet state and then reinforced into a cloth.

Features:

1. The production speed is high, up to 400m/min.

2. Can make full use of short fibers.

3. The uniformity of the product web is better.

4. Large water consumption and high one-time investment.

Applications:

1. Specialty paper: dust/liquid filter paper, tea bag.

2. Industrial use: filters, insulating materials, sound-absorbing materials.

3. Medical use: medical backing, medical tape, surgical bag wrapping material.

4. Civil: wallpaper, etc.

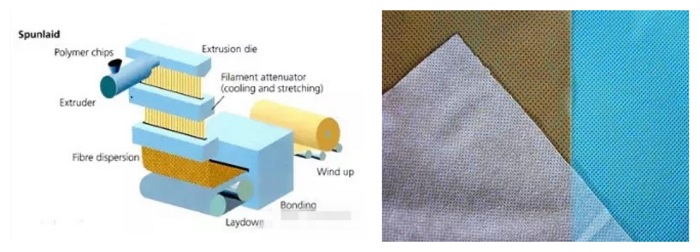

(5) Spunbond non-woven fabric

After the polymer has been extruded and stretched to form continuous filaments, the filaments are laid into a web, and the web is then bonded by itself, thermally bonded, chemically bonded or mechanically reinforced to make the web become non-woven. Spinning cloth.

Features:

1. The web is composed of continuous filaments.

2. Excellent tensile strength.

3. There are many process changes, and various methods can be used for reinforcement.

4. Wide variation range of filament size.

Applications:

1. Polypropylene (PP): geotextile, tufted carpet base cloth, coated base cloth, medical and sanitary materials, covering materials for disposable products, etc.

2. Polyester (PET): filter material, lining material, tufted carpet base cloth, agricultural material, packaging material, etc.

(Suntech ST-ASS Spunbond nonwoven machine)

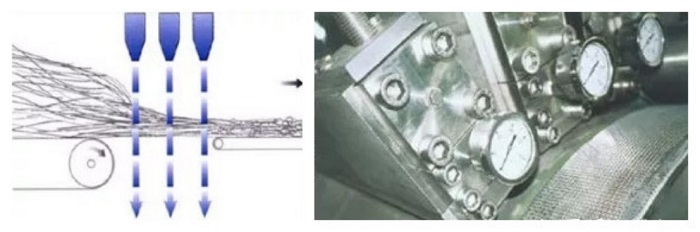

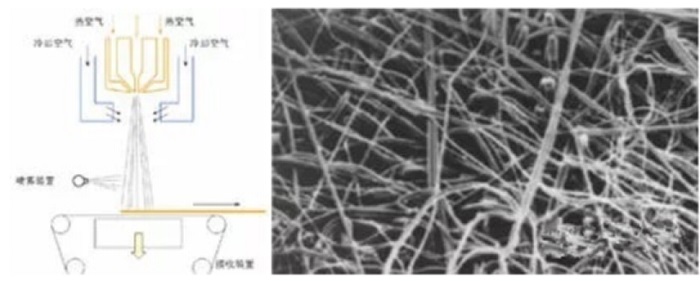

(6) Meltblown non-woven fabric

Spunmelt non-woven fabric is the core material of masks. It is mainly made of polypropylene and its fiber diameter can reach 1 to 5 microns. There are many voids, fluffy structure and good anti-wrinkle ability. The ultra-fine fibers with unique capillary structure increase the number and surface area of fibers per unit area, and have good filtration, shielding, heat insulation and oil absorption.

The process of meltblown non-woven fabric: polymer feeding-melt extrusion-fiber formation-fiber cooling-netting-reinforcement into cloth.

Features:

1. The fiber web is composed of extremely fine shorter fibers.

2. The fiber web has good uniformity and soft hand feeling.

3. Good filtration performance and liquid absorption performance.

4. The fiber web has poor strength.

Applications:

Filter materials, medical and health materials, clothing materials, battery diaphragm materials, wiping materials.

(Suntech ST-SMS Spunmelt nonwoven machine)

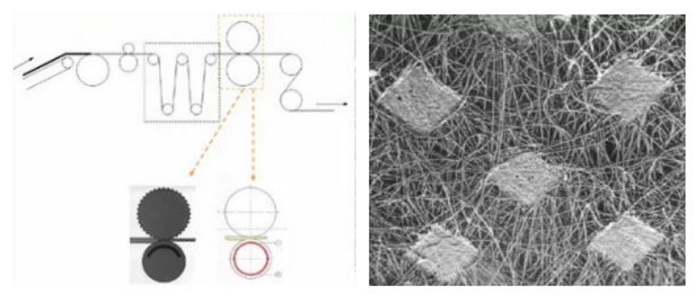

(7) Needle punched non-woven fabric

A type of dry-laid non-woven fabrics, needle-punched non-woven fabrics use the piercing effect of a needle to reinforce the fluffy web into a cloth.

Features:

1. Flexible entanglement between fibers, with good dimensional stability and elasticity.

2. Good permeability and filtration performance.

3. Feel plump and fluffy.

4. Various collection patterns or three-dimensional molded products can be manufactured according to requirements.

Applications:

Geotextile, geomembrane, velvet cloth, speaker blanket, electric blanket cotton, embroidered cotton, clothing cotton, Christmas crafts, artificial leather base cloth, special cloth for filter materials.

(8) Stitched non-woven fabric

Stitch-knitting non-woven fabric is a kind of dry-laid non-woven fabric. The stitch-knitting method uses a warp-knitted loop structure to bond fiber webs, yarn layers, non-woven materials (such as plastic sheets, plastic thin metal foils, etc.) or their combination The body is reinforced to make a non-woven fabric.

Features:

1. Durable, unchanging, resembling textiles, and feel good;

2. With health-care properties, promote blood circulation;

3. Wear resistance and good air permeability;

4. Waterproof;

5. Does not contain azo, heavy metals, etc., environmentally friendly and harmless;

6. The fabric formation speed is very fast, the production capacity is high, and it only takes a few minutes from feeding to fabric formation;

7. It can be made into products with flame retardant functions through post-finishing or directly using functional fibers;

8. Through dyeing and printing, it has rich colors and patterns.

Applications:

Disposable supplies, flour hardcover bags, fashion shopping bags, etc.

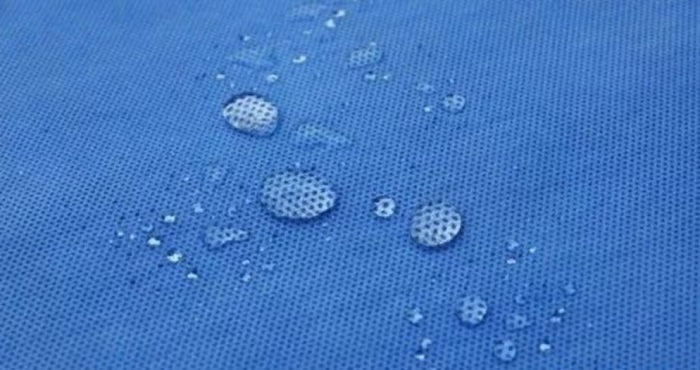

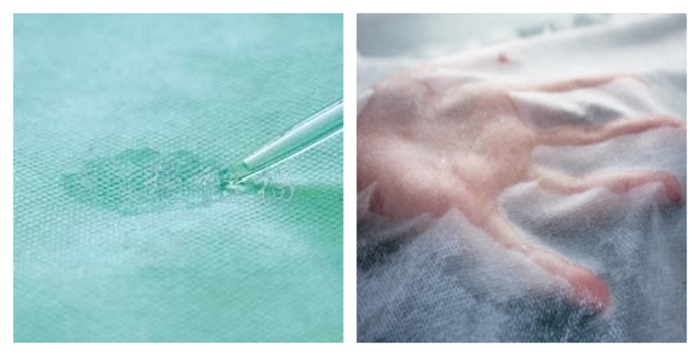

(9) Hydrophilic non-woven fabric

It is mainly used in the production of medical and sanitary materials to obtain a better hand feeling and not scratch the skin. For example, sanitary napkins and sanitary pads use the hydrophilic function of hydrophilic non-woven fabrics.

Features:

It has the ability to catch water and is hydrophilic and impregnated, which can quickly transfer liquid to the core.

Applications:

1. Diapers for babies, wipes for household life, sanitary napkins for ladies, etc.

2. Protective clothing, disinfection wraps, masks, diapers, civil wipes, wipes, wet face towels, magic towels, soft towel rolls, beauty products.

Environmental value of non-woven fabric

In addition to being widely used, non-woven fabrics also make outstanding contributions to environmental protection. Currently, most of the non-woven fabric raw materials used are polypropylene, while the raw material of plastic bags is polyethylene. Although the names of the two are similar, the chemical structure is quite different. Polyethylene is quite stable and difficult to degrade. It takes 300 years for plastic bags to be decomposed. Polypropylene has a weak chemical structure and easily breaks its molecular weight. It can be effectively degraded, and it will enter the next environmental cycle in the non-toxic province of Thailand. The woven bag can be completely decomposed within 90 days, and the non-woven bag can be reused more than 10 times. After being discarded, the pollution to the environment is only 10% of the plastic bag.

(Suntech ST-ANBM Non-woven bag machine)

Suntech provides mask production lines and health and hygiene production lines, including mask equipment, spunmelt non-woven fabrics and spunbond non-woven fabrics and other mask raw materials, spunlace non-woven machines, non-woven bag machines and non-woven bags and spunlace non-wovens The finished fabrics help environmental protection and care for the healthy life of human beings.

.jpg)