Automatic packaging machines are specialized devices designed to efficiently package fabric rolls for transportation and storage. These machines streamline the handling of fabric rolls, making them indispensable in the garment industry. By enveloping fabric around a paper tube and using suitable packing materials, these machines can operate both manually and automatically.

Constructed typically from durable materials like stainless steel, automatic packaging machines are cylindrical and have a loading capacity ranging from 200 to 400kg, accommodating various fabric rolls. The process involves compressing the fabric roll to reduce its size, facilitating easier transportation and protecting it from moisture and external wear. After compression, the fabric roll is securely sealed within a plastic bag or container for added protection.

Working Principles of Automatic Fabric Roll Packing Machines

Automatic fabric roll packing machines are engineered to efficiently package various types of fabric, including cotton, linen, and synthetic materials. The operation begins by rolling the fabric onto a spindle. A system of belts and pulleys then secures the fabric roll in place, initiating the packing process. The machine shapes the fabric roll into the desired form—such as roll to roll, plait to roll, or frame to roll—and continues until the roll is fully packed.

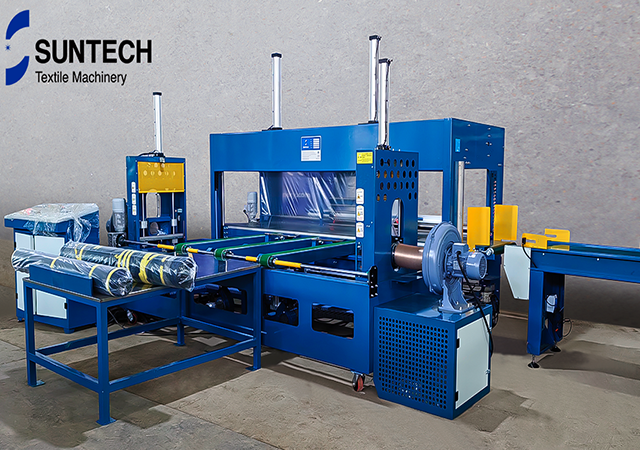

SUNTECH Automatic Fabric Roll Packing Machine (ST-ARPM)

The SUNTECH automatic fabric roll packing machine exemplifies advanced automation in the packaging process. Designed for vacuum-sealed and automated packing, this machine significantly reduces the need for manual labor. Key features include the ability to handle 3360 rolls per shift, vacuum packing, labeling functionality, intelligent sorting, and seamless ERP system integration. This machine not only streamlines the packing process but also enhances efficiency and productivity.

Features of ST-ARPM

High Capacity and Efficiency

The ST-ARPM can handle up to 7 rolls per minute, optimizing the packing process for maximum output.

Intelligent Classification

Smart categorization eliminates the need for manual sorting. The machine integrates with ST-Thinkor for accurate fabric roll inspection and quality control before packing and labeling, saving time and reducing defects.

Customization Options

The packing line can be tailored to accommodate various fabric roll sizes, shapes, and types, from delicate silk to robust industrial textiles, ensuring seamless handling regardless of the material.

AI-Powered Technologies

The system includes AI inspection, using computer vision algorithms to identify defects in fabric rolls, ensuring that only high-quality rolls are packed. It also incorporates sampling and taping functions, autonomously extracting samples for quality control and applying tape to secure the rolls during transit or storage.

Mapping and Labeling

Advanced mapping capabilities record and track the precise location of each fabric roll, facilitating efficient inventory management. Automated labeling accurately affixes product details, batch numbers, and barcodes to each roll, aiding in effortless identification and tracking across the supply chain.

Efficient Packing Process

The system uses the most suitable packing methods to neatly and securely package fabric rolls, ensuring their protection during transportation. It accommodates various packing styles and configurations to meet diverse packaging requirements.

Sorting Function

The ST-ARPM efficiently organizes rolls based on specific criteria such as size, color, or destination, simplifying the logistics process and enhancing distribution efficiency.

Conclusion

The SUNTECH Automated Fabric Roll Packing Line represents a significant advancement in fabric roll packaging technology. Its comprehensive features and intelligent design maximize productivity, allowing a single operator to oversee the entire process. By integrating AI inspection, sampling and taping, mapping, labeling, packing, and sorting, this machine provides a fully customizable one-stop solution for optimal efficiency, accuracy, and quality control in fabric roll packing.