I Events

Quality assurance plays a paramount role in ensuring customer satisfaction and brand credibility in the textile industry. One of the most critical aspects of quality control is visual inspection. Visual inspection not only identifies fabric defects but also helps maintain consistent quality throughout the production process.

Visual inspection involves manually examining textile products at various stages of production to detect flaws, defects, or irregularities. Skilled inspectors use their expertise, sharp eyesight, and sometimes specialized tools to scrutinize fabrics, garments, and accessories. This meticulous process helps maintain high standards, minimizes customer complaints, and reduces the risk of faulty products reaching the market.

1. Quality Assurance: Visual inspection is crucial for ensuring the quality of textiles. It helps identify defects such as misprints, stains, irregular stitching, color variations, or fabric flaws that can compromise the integrity and appearance of the final product. By detecting these issues early on, manufacturers can take corrective measures, ensuring the delivery of superior-quality textiles to customers.

2. Customer Satisfaction: In today's competitive market, customers have high expectations when it comes to the quality of textile products. By conducting visual inspections, textile manufacturers can identify and rectify any faults before the products reach the hands of consumers. This not only enhances customer satisfaction but also fosters brand loyalty and positive word-of-mouth.

3. Compliance with Industry Standards: The textile industry is subject to various regulations and quality standards, such as those set by international organizations or regional bodies. The visual inspection helps manufacturers ensure their products meet these stringent requirements, enabling them to comply with industry standards and maintain their reputation as reliable suppliers.

Early Defect Detection: Visual inspection allows for the identification of defects at an early stage of production. By catching issues before they escalate, manufacturers can reduce waste, save costs, and prevent large-scale quality problems that could affect the entire production batch.

Improved Efficiency: Integrating visual inspection into the production process enhances efficiency by streamlining quality control. Instead of relying solely on post-production checks or relying on customer feedback, inspecting textiles at different stages helps identify and rectify defects promptly, minimizing rework and ensuring timely delivery.

Enhanced Brand Reputation: Consistently delivering high-quality textile products positively impacts brand reputation. Visual inspection serves as a preventive measure against product recalls, returns, and dissatisfied customers. By investing in quality control, manufacturers build trust with consumers, gain a competitive edge, and establish a reputation for excellence.

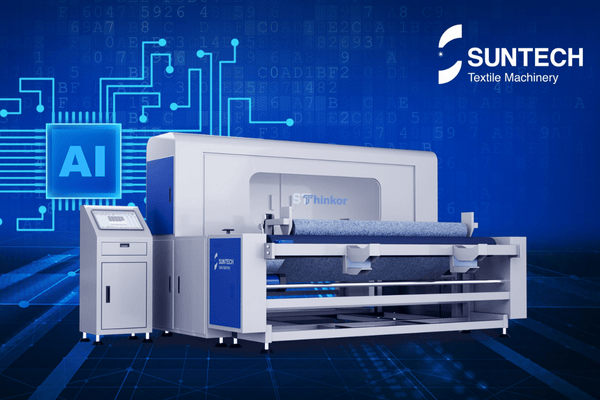

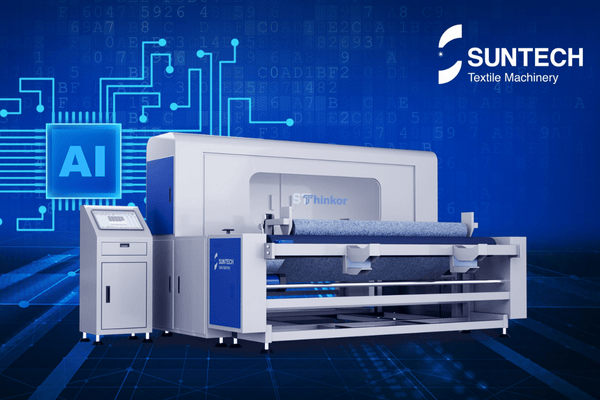

Human Error: Visual inspection relies on human judgment and eyesight, making it susceptible to errors. To mitigate this challenge, manufacturers can provide comprehensive training to inspectors, enabling them to identify a wide range of defects accurately. Additionally, integrating automated systems, such as computer vision technology, can augment human inspection capabilities and reduce errors.

Scalability: As textile production scales up, conducting visual inspections on every single item becomes impractical. Implementing sampling techniques, where a representative sample is inspected, can help strike a balance between accuracy and efficiency. Random and systematic sampling methods can ensure thorough inspection without slowing down production.

Subjectivity: Different inspectors may have slight variations in their interpretation of defects. Standardizing inspection criteria, using detailed guidelines, and conducting regular calibration exercises can help minimize subjectivity and ensure consistent quality control across different inspectors.

Visual inspection is an indispensable component of quality control in the textile industry. By meticulously scrutinizing textiles for defects, manufacturers can maintain high standards, enhance customer satisfaction, and comply with industry regulations. Despite challenges, technological advancements and standardized processes can improve the effectiveness and efficiency of visual inspection, contributing to the overall success of textile production and brand reputation.

Understanding Visual Inspection

Visual inspection involves manually examining textile products at various stages of production to detect flaws, defects, or irregularities. Skilled inspectors use their expertise, sharp eyesight, and sometimes specialized tools to scrutinize fabrics, garments, and accessories. This meticulous process helps maintain high standards, minimizes customer complaints, and reduces the risk of faulty products reaching the market.

1. Quality Assurance: Visual inspection is crucial for ensuring the quality of textiles. It helps identify defects such as misprints, stains, irregular stitching, color variations, or fabric flaws that can compromise the integrity and appearance of the final product. By detecting these issues early on, manufacturers can take corrective measures, ensuring the delivery of superior-quality textiles to customers.

2. Customer Satisfaction: In today's competitive market, customers have high expectations when it comes to the quality of textile products. By conducting visual inspections, textile manufacturers can identify and rectify any faults before the products reach the hands of consumers. This not only enhances customer satisfaction but also fosters brand loyalty and positive word-of-mouth.

3. Compliance with Industry Standards: The textile industry is subject to various regulations and quality standards, such as those set by international organizations or regional bodies. The visual inspection helps manufacturers ensure their products meet these stringent requirements, enabling them to comply with industry standards and maintain their reputation as reliable suppliers.

Benefits of Visual Inspection

Early Defect Detection: Visual inspection allows for the identification of defects at an early stage of production. By catching issues before they escalate, manufacturers can reduce waste, save costs, and prevent large-scale quality problems that could affect the entire production batch.

Improved Efficiency: Integrating visual inspection into the production process enhances efficiency by streamlining quality control. Instead of relying solely on post-production checks or relying on customer feedback, inspecting textiles at different stages helps identify and rectify defects promptly, minimizing rework and ensuring timely delivery.

Enhanced Brand Reputation: Consistently delivering high-quality textile products positively impacts brand reputation. Visual inspection serves as a preventive measure against product recalls, returns, and dissatisfied customers. By investing in quality control, manufacturers build trust with consumers, gain a competitive edge, and establish a reputation for excellence.

Challenges and Solutions

Human Error: Visual inspection relies on human judgment and eyesight, making it susceptible to errors. To mitigate this challenge, manufacturers can provide comprehensive training to inspectors, enabling them to identify a wide range of defects accurately. Additionally, integrating automated systems, such as computer vision technology, can augment human inspection capabilities and reduce errors.

Scalability: As textile production scales up, conducting visual inspections on every single item becomes impractical. Implementing sampling techniques, where a representative sample is inspected, can help strike a balance between accuracy and efficiency. Random and systematic sampling methods can ensure thorough inspection without slowing down production.

Subjectivity: Different inspectors may have slight variations in their interpretation of defects. Standardizing inspection criteria, using detailed guidelines, and conducting regular calibration exercises can help minimize subjectivity and ensure consistent quality control across different inspectors.

Conclusion

Visual inspection is an indispensable component of quality control in the textile industry. By meticulously scrutinizing textiles for defects, manufacturers can maintain high standards, enhance customer satisfaction, and comply with industry regulations. Despite challenges, technological advancements and standardized processes can improve the effectiveness and efficiency of visual inspection, contributing to the overall success of textile production and brand reputation.