The international covid-19 situation continues to worsen. The number of people diagnosed with covid-19 worldwide has reached more than 20 million. Among them, the number of confirmed cases in the United States is close to 18 million, and 5.2 out of every 100 Americans are infected. Although the vaccine has already come out, it will take time to spread. It is also necessary to wear a mask. Even if the vaccine is effective, wearing a mask will become preventive daily equipment. But there are many kinds of masks, which kind of mask is suitable for epidemic prevention?

Common masks include surgical masks, N95 masks, cotton masks, activated carbon masks, sponge masks, etc. Let's compare the effects of these five masks.(Click to share to LinkedIn)

1. Surgical mask: can effectively filter bacteria

The structure of surgical masks is usually divided into three layers: the outer layer is anti-wave splashing, the middle layer has a filtering effect, the inner layer can absorb moisture, and has a 90% barrier effect on particles above 6μm, so it can block most of the droplet infectious bacteria.

Suitable for use when there is a cold, fever and other respiratory symptoms, or when going to hospitals, movie theaters and other unventilated places.(Click to share to Facebook)

2. N95 mask: can effectively filter bacteria

The N of N95 mask means that the mask is suitable for use in non-oily occasions. 95 means that it can filter more than 95% of dust, including droplets and some toxic gases. Because this kind of mask is very dense, it may feel difficult to breathe after wearing it. Therefore, in the prevention of daily diseases, ordinary people use surgical masks.

Suitable for use during the epidemic period of droplet infection and extremely poor air environment, mainly for medical staff or employees of chemical plants.

3. Cotton mask: can not isolate bacteria

Cotton masks are mainly used to avoid inhaling dust or spraying droplets, and mainly filter large particles such as dust and other foreign objects.

Suitable for: general cleaning work, general warmth on weekdays or temporary replacement when surgical masks are not available.

4. Activated carbon mask: can not isolate bacteria

Activated carbon masks can absorb organic gases because of the addition of an activated carbon layer, and the fiber pores of the filter layer are smaller than cotton masks, so they can absorb organic solvents emitted by steam-attached locomotives.

Suitable for: outdoor cycling, painting, spraying, spraying of pesticides, etc. It is not effective in preventing the penetration of suspended particles and bacteria, so it is less recommended for epidemic prevention.

5. Sponge mask: can not isolate bacteria

Sponge masks (polyurethane masks) are soft and comfortable in texture, and have good air permeability, but they are mainly used to filter pollen, dust, and smog, and they have poor anti-virus capabilities.

Suitable for: blocking pollen, dust, smog

The only masks that can really prevent and control the covid-19 are surgical masks and N95 masks? Why? First, the filter principle of the mask is analyzed. The filter methods of the mask include mechanical filter and electrostatic adsorption.

1. Mechanical filtration: virus and other impurities are intercepted by mechanical means. Mechanical filtration can be divided into the following categories:

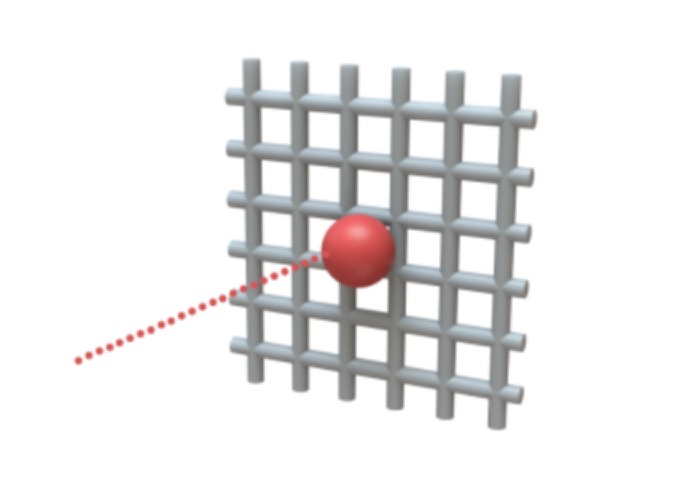

A.Interception effect. If you think of a mask as a sieve, the particles larger than the size of the sieve can't pass through. This is part of the interception effect. The main target is larger particles.

(Interception effect)

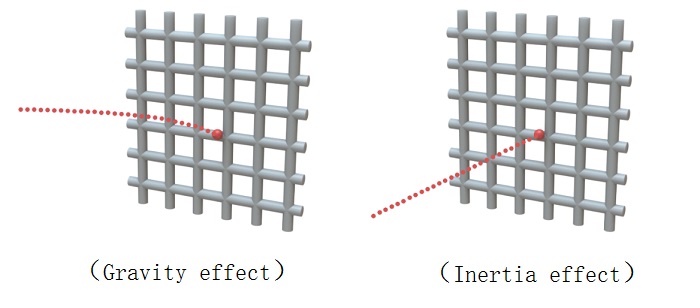

B.Gravity effect and inertia effect. Although some particles can pass through the gap between the fibers, because of the inertia and gravity under the air flow, they will also hit the fibers and be trapped, unable to pass through the filter material together with the air. These two kinds of effects are called gravity effect and inertia effect respectively. These two kinds of effects also mainly act on the particles with larger mass.

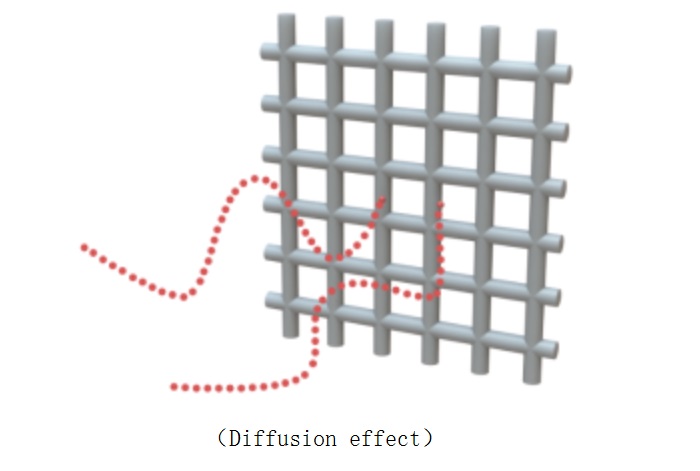

C. Diffusion effect. There are some very small particles in the air, not as regular as the larger particles along a certain path of motion, but will do random motion, this is Brownian motion. At room temperature, the diffusion distance of 0.1 μ m particles in one second can reach 17 μ m, which is much larger than the distance between fibers. Therefore, these particles are also very easy to contact with fibers and have a greater chance of being intercepted. This is called diffusion effect. For particles larger than 3 microns, the diffusion effect is very weak. The smaller the particles are, the slower the flow velocity is, and the more obvious the diffusion effect is.

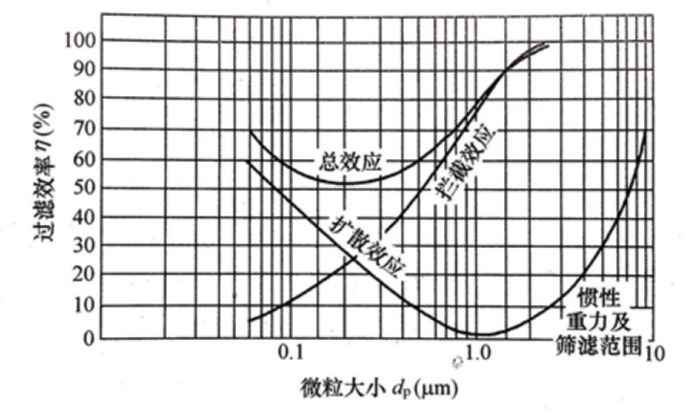

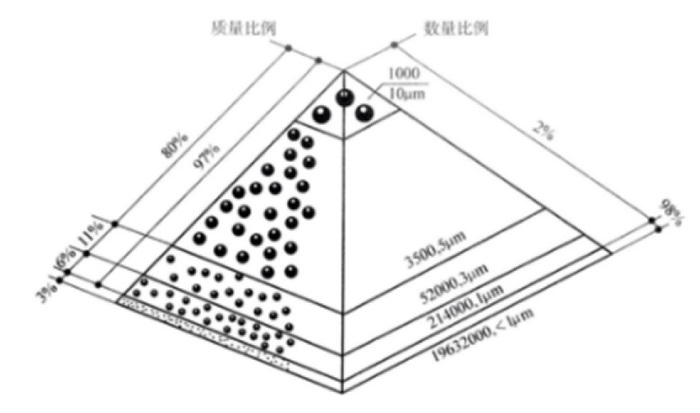

Based on the above discussion, the larger particles will be easily intercepted through the interception effect, gravity effect and inertia effect, while the smaller particles will be well intercepted through the diffusion effect, that is to say, the middle size particles are the most difficult to be intercepted. The relationship between filtration effect and particle size is shown in the figure below. The particle size corresponding to the position with the lowest total effect is called the minimum efficiency particle size.

(Relationship between particle size and filtration efficiency)

(Pyramid of particle distribution in air)

Many experiments have proved that the minimum effective particle size varies with different properties of particles, different fiber layers and different filtration speeds. However, in most cases, the minimum efficiency particle size is between 0.1-0.4 μ m, and a large part of PM2.5 particles are in this size range.

Is it possible to make the hole on the filter screen small enough to filter out most of the particles in the air as small as 0.1 micron? This can filter out the vast majority of particles, but the filtration resistance is too large, which will seriously affect the breathing. What should I do?

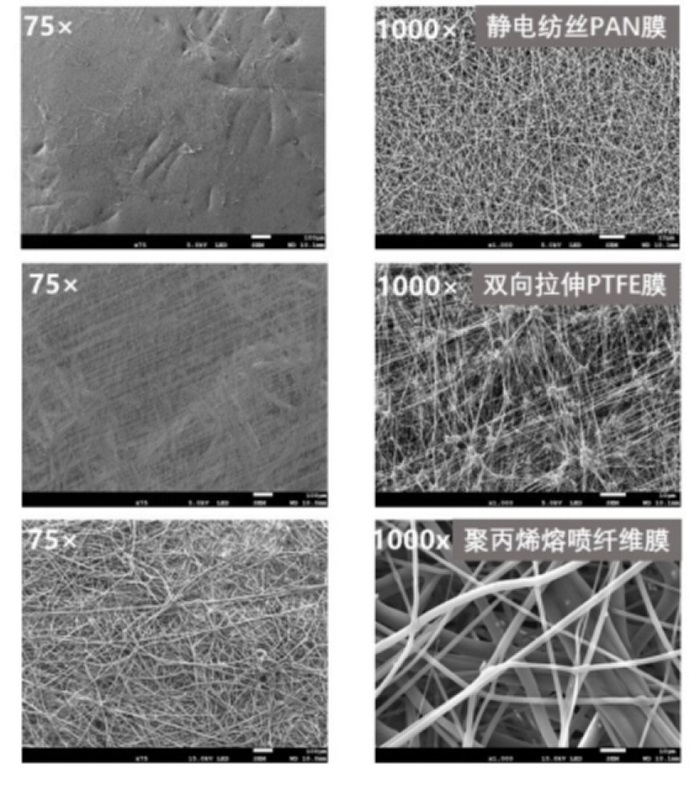

Method 1: make the filter membrane thin: make the filter layer very thin to reduce the air resistance. Now many nano filter membranes are very thin, such as the PTFE nano membrane for masks, which is thinner than 10 microns (0.01 mm); the nano membrane prepared by electrospinning is generally thinner than 10 microns, but the strength of such a membrane is very low, so it must be compounded with higher strength large pore non-woven fabric Support. Compared with the single-layer melt blown fabric, the thickness of the single-layer melt blown fabric is more than 95 microns. The second way is to make the filter material have electrostatic adsorption capacity.

(Micro morphology of different kinds of filter membrane fibers)

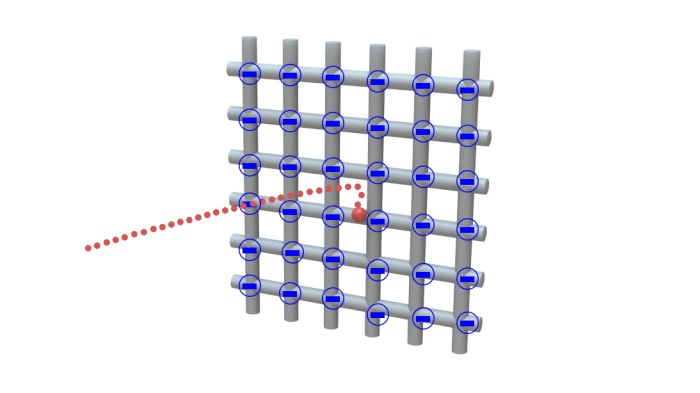

Method 2 :electrostatic adsorption: charge is injected into polypropylene melt blown cloth by various methods to make the melt blown cloth static and keep this state for a long time. When the particles in the air pass through the mask, they will be absorbed by the increased electrostatic action, thus greatly improving the overall filtration efficiency without increasing the respiratory resistance. Electrostatic adsorption plays an important role in the filtration of particles between 0.1 and 0.4 microns which are difficult to be intercepted by mechanical filtration.

(Electrostatic attraction of light small objects)

High quality medical surgical masks and medical protective masks such as N95 masks are based on the above two filtration mechanisms, taking into account the low filtration resistance and high filtration efficiency. Among them, electrostatic adsorption is the key technology of bacteria isolation, and the key layer of medical surgical mask and medical N95 mask is the melt blown cloth with electrostatic adsorption. In some places where there is a lack of masks, people like to use cotton cloth, diapers, scarves and other homemade masks, but these masks are unable to achieve epidemic prevention effect due to the lack of melt blown cloth layer.

(Schematic diagram of electrostatic adsorption)

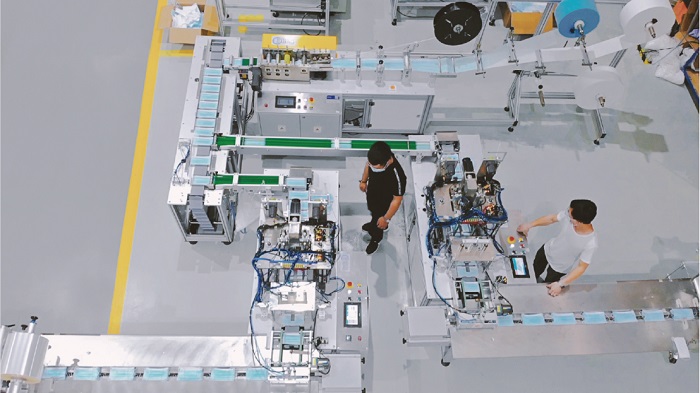

Suntech has focused on the field of personal health and sanitation equipment for 46 years, specializing in the production of mask machines, melt blown machines, spunbond non-woven machines, spunmelt non-woven machines and other mask machinery based on the standards of "China Seiko Intelligent Manufacturing". It has mature mask machinery The professional team with rich technology and experience provides overseas support, perfect after-sales service, good reputation and high return rate.

Suntech integrated automatic mask machine includes intelligent functions such as automatic adjustment of tightness, automatic edge alignment, visual inspection, UV sterilization and disinfection. It is controlled by touch screen. One device covers the whole process of mask production. The production speed of surgical mask machine is as high as 120-160 pieces/ Minutes, the production speed of N95 mask machine (earloop) is as high as 80 pieces/min, and the production speed of N95 mask machine (head strap) is as high as 40 pieces/min.

(ST-AMM mask machine,Click to contact)

Manufacturers that produce masks for a long time should also deploy meltblown production lines. Unqualified meltblown machines may not be able to produce qualified masks after several months of debugging, seriously delaying production progress.

(ST-AMB melt blown machine,Click to contact)

If you don’t want to buy a melt blown machine, you can also directly buy mask materials such as melt blown cloth and spunbond non-woven fabric.