The data highlights a notable growth trajectory in China's textile machinery sector from 2015 to 2019. Import figures for water jet looms surged from 1,025 units to 3,222 units, exhibiting a robust compound annual growth rate of 33.15%. Air jet looms experienced a steady rise from 4,305 units to 6,446 units, with a compound annual growth rate of 10.62%. However, high-speed rapier looms faced a decline, dropping from 2,561 units to 1,703 units at a compound annual growth rate of -9.70%. Despite progress, the weaving machinery industry in China is notably deficient in air jet looms and water jet looms, relying heavily on imports.

In terms of exports, China primarily exports rapier looms, amounting to 14,500 units in 2019. Nevertheless, there has been a shift in the composition of total weaving machinery exports. The proportion of rapier looms decreased from 64% to 50% from 2015 to 2019, while the share of water jet and air jet looms increased steadily.

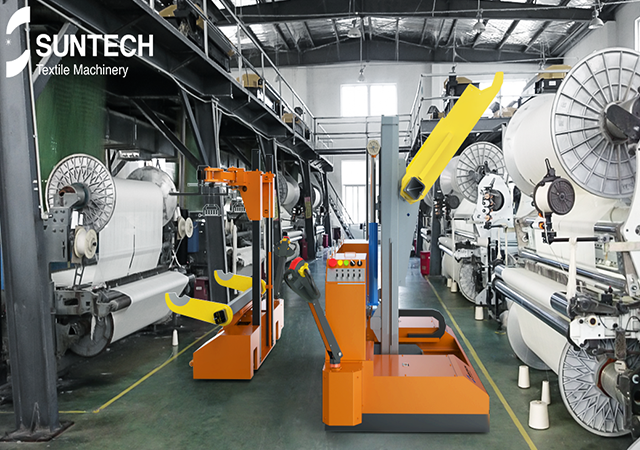

SUNTECH Textile Machinery: A Trailblazer in the Industry

As a trailblazer in the textile machinery sector, SUNTECH Textile Machinery remains steadfast in its commitment to advancing research, development, and innovation, ushering in a new era of possibilities for the entire industry. SUNTECH's core philosophy centers on the belief that cutting-edge technology and collaborative efforts pave the way for a bright future in the textile machinery industry.

The SUNTECH STelego series stands out as a prime example, offering a comprehensive range of motorized beam trolleys designed with precision. These trolleys revolutionize the unloading and loading process of warp and cloth beams from looms, streamlining operations across various working environments. The user-friendly design and seamless operation make these trolleys indispensable, significantly reducing labor costs, enhancing efficiency, and boosting productivity.

SUNTECH's "ST-Thinkor," an intelligent fabric inspection system, has garnered widespread adoption across diverse industries, transforming fabric production processes. The system seamlessly integrates with various machinery, ensuring heightened efficiency and accuracy throughout the production process. With a remarkable 95% defect detection rate, "ST-Thinkor" surpasses conventional manual inspection methods, setting a new standard in fabric inspection.

The upgraded fabric relaxing machine, ST-FRM-VI(P), is another innovation by SUNTECH. Operating with two separate motors and inverters, it ensures a tension-free feed and 100% tension release for knitted fabrics, making it an ideal choice for textile enterprises.

The textile machinery industry, a crucial pillar of support for textile production, faces evolving challenges and opportunities. SUNTECH Textile Machinery stands at the forefront, consistently addressing these challenges through research, development, and innovation. Over the years, SUNTECH has witnessed significant breakthroughs in technology and design, introducing advanced automation technology and intelligent solutions to enhance production efficiency and reduce environmental impact.

With SUNTECH Textile Machinery leading the way, the textile industry can confidently anticipate a future marked by increased efficiency, sustainability, and progress.